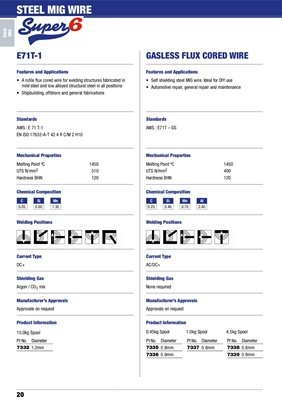

Welding Positions

C

0.05

Standards

Mechanical Properties

Si

0.60

Mn

1.30

AWS : E 71 T-1

EN ISO 17632-A-T 42 4 R C/M 2 H10

Melting Point ºC 1450

UTS N/mm2 510

Hardness BHN 120

Features and Applications

• A rutile flux cored wire for welding structures fabricated in

mild steel and low alloyed structural steel in all positions

• Shipbuilding, offshore and general fabrications

Product Information

Current Type

DC+

Shielding Gas

Argon / CO2 mix

Chemical Composition

15.0kg Spool

Approvals on request

Manufacturer's Approvals

E71T-1

Welding Positions

Standards

Mechanical Properties

C Si

0.25

Mn

0.70

Al

2.40

0.40

AWS : E71T - GS

Melting Point ºC 1450

UTS N/mm2 400

Hardness BHN 120

Features and Applications

• Self shielding steel MIG wire. Ideal for DIY use

• Automotive repair, general repair and maintenance

Product Information

Current Type

AC/DC+

Shielding Gas

None required

Approvals on request

Manufacturer's Approvals

Chemical Composition

0.45kg Spool

1.0kg Spool

4.5kg Spool

GASLESS FLUX CORED WIRE

STEEL MIG WIRE

Pt No. Diameter

7332 1.2mm

Pt No. Diameter

7337 0.8mm

Pt No. Diameter

7335 0.8mm

7336 0.9mm

Pt No. Diameter

7338 0.8mm

7339 0.9mm

20

Steel

MIG