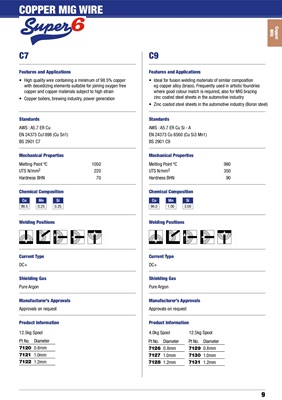

COPPER MIG WIRE

9

Welding Positions

Standards

Mechanical Properties

Cu

99.5

Mn

0.25

Si

0.25

AWS : A5.7 ER Cu

EN 24373 Cu1898 (Cu Sn1)

BS 2901 C7

Melting Point ºC 1050

UTS N/mm2 220

Hardness BHN 70

Features and Applications

• High quality wire containing a minimum of 98.5% copper

with deoxidizing elements suitable for joining oxygen free

copper and copper materials subject to high strain

• Copper boilers, brewing industry, power generation

Current Type

DC+

Shielding Gas

Pure Argon

Chemical Composition

Product Information

12.5kg Spool

Approvals on request

Manufacturer's Approvals

C7

Pt No. Diameter

7120 0.8mm

7121 1.0mm

7122 1.2mm

Welding Positions

Standards

Mechanical Properties

Cu

96.0

Mn

1.00

Si

3.00

AWS : A5.7 ER Cu Si - A

EN 24373 Cu 6560 (Cu Si3 Mn1)

BS 2901 C9

Melting Point ºC 980

UTS N/mm2 350

Hardness BHN 90

Features and Applications

• Ideal for fusion welding materials of similar composition

eg copper alloy (brass). Frequently used in artistic foundries

where good colour match is required, also for MIG brazing

zinc coated steel sheets in the automotive industry

• Zinc coated steel sheets in the automotive industry (Boron steel)

Current Type

DC+

Shielding Gas

Pure Argon

Chemical Composition

Product Information

Approvals on request

Manufacturer's Approvals

4.0kg Spool 12.5kg Spool

C9

Pt No. Diameter

7126 0.8mm

7127 1.0mm

7128 1.2mm

Pt No. Diameter

7129 0.8mm

7130 1.0mm

7131 1.2mm

Copper

MIG