Working environment

• Using these tools in any potentially explosive environment is strictly prohibited

• It is always recommended that these types of tools must be operated when standing on a solid or firm location

• Always use these tools in a well ventilated area

• Slipping, stumbling and falling are the major causes of potential serious injury, therefore, a clean and clutter free surface

in the working area before operating the tools is strongly recommended

Air supply and connection requirements

• The maximum recommended air pressure during operation must not exceed 90 PSI (6.3 Bar). Higher air pressure may create

unsafe operating conditions for the tool and the user

• The compressed air should be cooled and have a water filter installed at the outlet end of the compressor. Even with a water filter

installed, some water may still condense in the piping or hose and will enter the tool mechanism causing premature damage to

the tool. Therefore, it is recommended to install an air filter-lubricator device somewhere between the tool and the compressor

• Always use an air compressor of the proper capacity to operate each tool

• Clean the hose with a blast of compressed air before connecting the hose to the air tool. This will prevent both moisture and dust

inside the hose from entering the tool and causing possible rust or malfunction

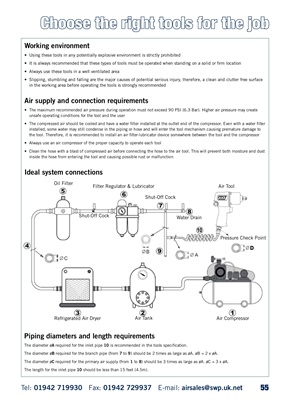

Ideal system connections

Oil Filter

Shut-Off Cock

Shut-Off Cock

Air Tool

Water Drain

Pressure Check Point

Filter Regulator & Lubricator

Refrigerated Air Dryer Air Tank Air Compressor

Piping diameters and length requirements

The diameter øA required for the inlet pipe 10 is recommended in the tools specification.

The diameter øB required for the branch pipe (from 7 to 9) should be 2 times as large as øA. øB = 2 x øA.

The diameter øC required for the primary air supply (from 1 to 8) should be 3 times as large as øA. øC = 3 x øA.

The length for the inlet pipe 10 should be less than 15 feet (4.5m).

Choose the right tools for the job

55

Tel: 01942 719930 Fax: 01942 729937 E-mail: airsales@swp.uk.netttp://swp.uk.net" target="_blank" title="Visit swp.uk.net">swp.uk.net