208

Visit: www.vet-direct.com for all your vet supplies FREE Phone 0800 068 3300 FREE Fax 0800 068 3311Instruments & Implants

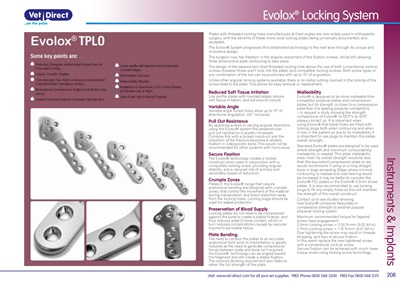

Reduced Soft Tissue Irritation

Low profile plates with rounded edges reduce

soft tissue irritation, and aid wound closure.

Variable Angle

Variable angle Screw holes allow up to 10° of

directional angulation. (20° inclusive).

Pull Out Resistance

By opposing screws in varying angular directions

using the Evolox® system the perpendicular

pull out resistance is greatly increased.

Combine this with a locked construct and the

reduction of the fracture becomes a reliable

fixation in osteoporotic bone. This would not be

recommended for other systems with mono-axial.

Secure Fixation

The Evolox® technology creates a locked

construct when used in conjunction with a

compatible locking screw, providing angular

stability, and a reduced risk of primary and

secondary losses of reduction.

Crumple Zones

Plates in the Evolox® range that require

anatomical bending are designed with crumple

zones, that control the movement of the material

during manipulation and direct distortion away

from the locking holes. Locking plugs should be

used for added protection.

Preservation of Blood Supply

Locking plates do not need to be compressed

against the bone to create a stable fixation, and

thus reduces plate to bone contact, which in

turn reduces complications caused by vascular

trauma to periosteal tissue.

Plate Bending

The need to contour the plates to an accurate

anatomical form prior to implantation is greatly

reduced as the need to generate compressive

forces between plate and bone isn't required,

the Evolox® technology can be angled toward

the fragment and still create a stable fixation.

The reduced bending requirement also helps to

retain the full strength of the plate.

Malleability

Evolox® is designed to be more malleable than

competitor polyaxial plates and compression

plates but its strength is closer to a compression

plate than the leading polyaxial competitors

- to request a study showing the strength

comparisons of Evolox® Vs DCP's Vs SOP,

please contact us. It is important when

using Evolox® that blank holes are filled with

locking plugs both when contouring and when

in situ in the patient as due to its malleability it

is important to use plugs to maintain the plates

overall strength.

Standard Evolox® plates are designed to be used

where strength and maximum contourability/

malleability is needed. This plate malleability

does mean its overall strength would be less

than the equivalent compression plate so we

would recommend if using on a long straight

bone in dogs exceeding 30kgs where minimal

contouring is needed and load bearing would

be increased it may be better to consider the

Evolox® PCL plates or the Evolox® 3.5mm broad

plates. It is also recommended to use locking

plugs to fill any empty holes as this will maintain

the strength of the overall construct.

Contact us to see studies showing

how Evolox® compares favourably in

comparative strength to another popular

polyaxial locking system

Maximum recommended torque for tapered

screw head engagement:

3.5mm Locking screw = 2.30 N-mm (0.02 lbf-in)

2.7mm Locking screw = 1.15 N-mm (0.01 lbf-in)

Over tightening the screw may result in threads

stripping, and loss of secure fixation.

In this event replace the over tightened screw

with a conventional cortical screw.

Secure fixation can be achieved with much lower

torque levels using locking screw technology.

Plates with threaded locking holes manufactured at fixed angles are now widely used in orthopaedic

surgery, with the benefits of these mono-axial locking plates being universally documented, and

accepted.

The Evolox® System progresses this established technology to the next level through its unique and

innovative design.

The surgeon now has freedom in the angular placement of the fixation screws, whilst still allowing

three dimensional plate contouring to take place.

The design of the tapered twin start threaded locking hole allows the use of both conventional cortical

screws (however these won't lock into the plate), and compatible locking screws. Both screw types or

any combination of the two can be positioned with up to 10° of angulation.

Unlike other angular locking systems available, there is no metal cutting involved in the locking of the

screw head to the plate. This allows for easy removal or replacement.

Evolox® Locking System